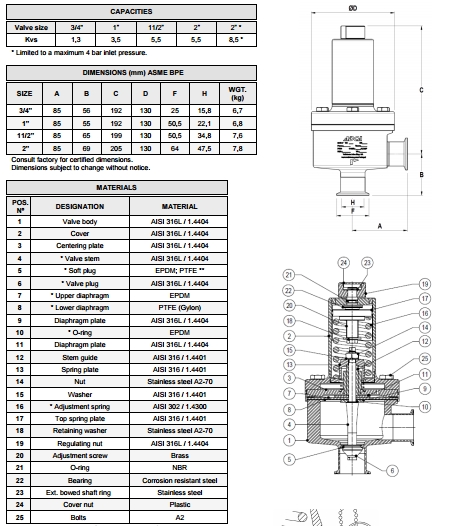

DESCRIPTION

The ADCA P160 series direct acting, spring-loaded diaphragm sensing, pressure reducing valves are designed for use with clean steam, compressed air, water and other gases or liquids compatible with the construction materials.

MAIN FEATURES

Compact design.

Completely machined from barstock material, no castings or forgings are used on the standard version.

No rising stem.

STANDARD SURFACE FINISH

Internal wetted parts: ≤ 0,51 micron Ra – SF1.

External: ≤ 0,76 micron Ra – SF3.

Other surface conditions see IS PV20.00 E – Technical information.

Ultrasonic cleaning.

OPTIONS:

Leakage line connection 1/8” (captured vent).

Different soft valves for liquids and gases.

Lock system, allows clean-in-place (CIP) and sterilization-in-place (SIP) operations with valve in line.

Gauge connection on body.

USE:

Clean steam, compressed air, water and other gases and liquids compatible with the construction.

AVAILABLE MODELS:

P160.

SIZES:

3/4”, 1”, 11/2”, 2”. 2-1/2”,3”.

OUTLET SPRING RANGES:

0,8 – 1,5 bar; 1 – 3 bar; 1,5 – 5 bar.

CONNECTIONS:

ASME BPE. Clamp ferrules or others on request.

PACKAGING:

Assembling and packaging in a clean room certified according to ISO 14644-1. The product is end capped and sealed with recyclable thermo-shrinkable plastic film, to avoid contamination.

INSTALLATION:

Horizontal installation. Inlet vertical and horizontal outlet angle connection. See IMI.

ORDER REQUIREMENTS:

Type of fluid. Maximum operating temperature. Inlet pressure and required outlet pressure. Capacity (maximum and minimum).

京ICP备15028267号-1 技术支持:普照新时空

: 306600038